Stamping parts are mainly formed by pressing with the help of pressure. 1060 aluminum alloy plate stamping parts have good plasticity and good ductility. With the rapid development of modern industrial manufacturing, it is everywhere and can be widely used. In the automobile, electronic appliances, machinery, instrumentation and other fields, specific information about the 1060 aluminum plate used in stamping parts is introduced and analyzed in detail.

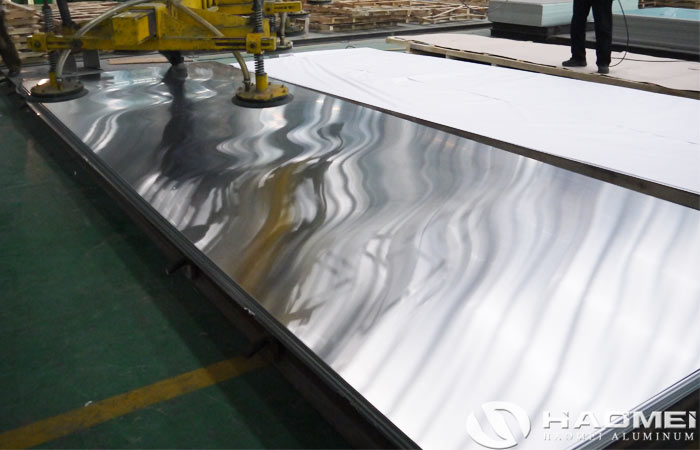

1060 aluminum alloy plate

1060 aluminum alloy plate specifications for stamping parts

Thickness: 0.1-500mm

Width: 100-2650mm

Material status: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Applicable fields: busbars, power battery flexible connections, aluminum-plastic panels, lighting materials, metal stamping parts, etc.

Performance characteristics: It has good corrosion resistance, excellent forming processing characteristics, high gloss, good electrical conductivity and welding performance, high elongation, and can hide the conventional stamping and stretching requirements.

According to different product specifications, the market quotation of 1060 aluminum sheet for stamping parts is different, and the pricing standards of different manufacturers are also different. The production strength of the 1060 aluminum sheet manufacturers is different, and the materials, technology, craftsmanship, etc. of the products themselves will be different. Therefore, The quality is different, so the quotation is different, so there is no fixed quotation in the market.

On the whole, you should not just look at the quotation when purchasing 1060 aluminum alloy plate. The quality, performance, and after-sales service system of the aluminum plate manufacturer should be comprehensively compared and considered for purchase. At present, the market as a whole shows an upward trend of 1060 aluminum sheet for stamping. It is recommended that you buy from direct-sale manufacturers. The ex-factory price is more preferential, and you can enjoy lower prices and more assured relative quality.