Aluminium plate ships have a clear advantage over steel ships with regards to total ownership costs. This is due to the fact that aluminium ships are lighter and use less fuel than steel ships. Aluminium ships also do not incur lifecycle maintenance costs associated with painting, and because they are generally smaller, they require less manning. And when an aluminium vessel reaches the end of its life span, it continues to provide significant benefits as a result of its high recycling value.

Aluminium alloy sheet is used not only in construction of tankers and big ships but also in yachts, motor boats, cutters as well as underwater craft. Most of sporting boats are built from aluminium, from keel to mast, which gives them a speed advantage, while high capacity vessels are built from steel. Nevertheless, the superstructure and other auxiliary equipment is made from aluminium to save weight and increase the cargo carrying capacity.

With all the existing technologies and methods available for aluminium shipbuilding, aluminum plate sheet has the potential to replace steel in the future as the main ship construction material. The use of aluminium alloys will especially grow in smaller ships and yachts while the long ships and tankers (over 130 m) will continue to be dominated by steel. All in all, the further about aluminium plate for ship building future in shipbuilding is bright.

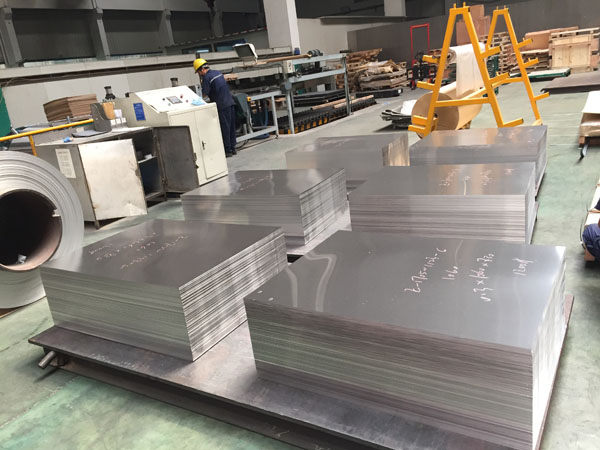

5083 marine aluminium sheet 20mm thick is popular in ship building, because of its properties:

1,With excellent corrosion resistance and weldability.

2,With welded structured requiring

3,It can be anodized inreased corrsion resistance.

4,Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

Any interests ,contact me freely.