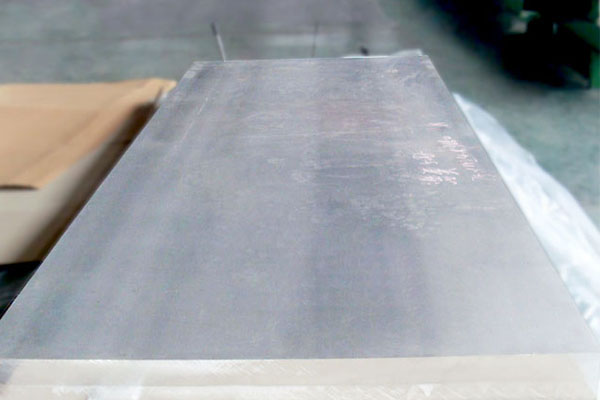

The topic of aluminium sheet metal properties is very broad, and this article aims to give a brief yet full introduction to properties of aluminium plates in physical and chemical way respectively.

From the physical point of view, aluminium sheet metal products have a low density, a good tensile strength, an excellent polishing effect, a good alloying property, a light weight and a high adaptability to mechanical processing methods. The aluminium metal has a density of only about 2.7, which is less than one third of copper and half of steel. This alone makes it advantageous over most regular metals in price and unit weight. A good tensile strength enables aluminium sheet metal pieces to go through deep drawing, spinning, casting, rolling and cutting processes in a given mechanical scope, based on which various semi-processed products are made, such as aluminum checker plates (embossing on the surface of an aluminium sheet), aluminium circle discs (further processed into cookware by deep drawing and spinning), aluminium strips (for bottle caps etc.) and so on. The excellent polishing effect of aluminium sheet metals enable people to produce mirror polished aluminium sheets applied for reflecting and decoration purposes. Last but not least, a perfect alloying property helps aluminum plates to realize changes and improvements in hardness, tensile strength, weight and certain chemical properties.

Chemically the aluminium sheet metal properties include a strong activity, an outstanding corrosion resistance and an excellent anodizing effect. Plain aluminium sheet metals are so active that they react to the oxygen in the air within minutes and a thin white oxide layer can be observed by the naked eye in a few days. This oxide layer, on the other hand, proves to be so stable in chemical properties that it serves as a protector of the inner part of the metal against corrosive materials. That’s how an aluminum sheet metal obtains a strong corrosion resistance! The excellent anodizing effect of an aluminum sheet plate refers to the fact that the plate can be easily further processed into an anodized aluminium sheet or mirror finish anodized aluminium sheet with assistance of the industrial anodizing method.