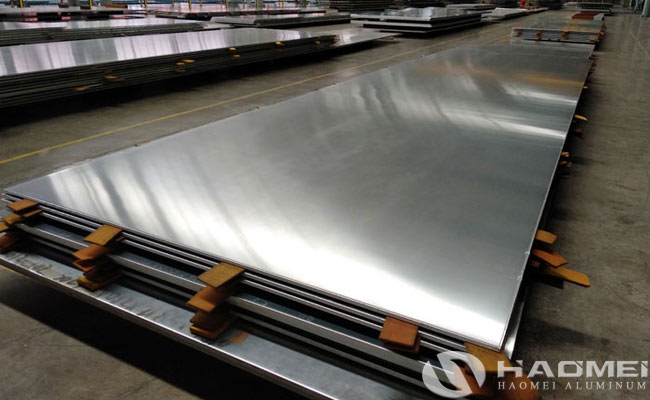

Aluminum alloy sheets are specified for countless uses that benefit from the inherent properties of the metal itself. Aluminum’s light weight, ease of processing, and thermal/electrical conductivity contribute to the performance of many products. The versatility and high speed of aluminum cast tooling plate for a variety of machining operations have advantages that make them a popular choice for molding complex parts.

When choosing aluminum tooling plate for applications where dimensional control is critical, design engineers must have confidence in precise tolerances and dimensional stability. Fixtures and quality control equipment demonstrate the need for close tolerances, where parts may require controlled thickness and flatness as the basis for tooling or measuring equipment. This type of portable gripper can be used in a variety of industries from aircraft to automobiles, computers to electronics, printing equipment to food processing machinery. The second consideration, dimensional stability, is an important factor in machining parts by removing large amounts of metal. Dimensional stability must be considered before and after processing, and in parts with large temperature changes.

To maintain critical dimensional tolerances, an important distinction is made between cast aluminum tooling plate and their forged fittings. Forged aluminum sheet is suitable for many purposes, but does not provide the tolerance control or stress relief features available in cast aluminum sheet. Therefore, a widely machined forged aluminum sheet product will not hold machining tolerances and will tend to flatten out. Cast tooling aluminum plate provides better dimensional stability.

Aluminum cast tooling plate are not new. In the 1950s, the development of large commercial jets such as the Boeing 707 and DC-8 required a higher level of tool precision and stability. Materials commonly used for molds at the time included rolled steel, rolled aluminum, plastic, wood and asbestos. In the assembly of giant fuselage and wing sections, none of these have the stability to ensure machining accuracy over a wide temperature range. Attention turns to aluminum, its light weight, smokeless properties, machinability and ease of work have led to preliminary trials of forged aluminum sheet as a tooling plate. These failed because there was no way to initially flatten the aluminum tooling plate and the forged material lacked dimensional stability.