As boat construction material, aluminum alloy 5052 5083 5086 in every important category!

First off, the 5XXX series of aluminum alloys are extremely popular on boats. These alloys offer weld yield strengths from 100 to 200 MPa and feature good weld ductility without the need for heat treatment. They are also renowned for their high corrosion resistance. Seawater tests have shown that after ten years of use, the tensile strength of 5XXX series alloys show reductions of only 2 to 5 percent.

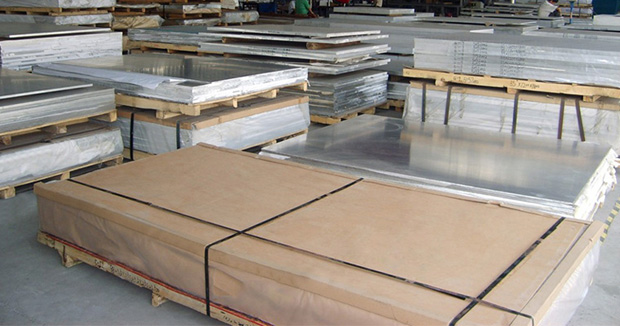

Three alloys that are considered marine grade are 5052, 5083, and 5086 aluminum alloy. All three are produced primarily as rolled materials (in sheet or plates) and are commonly found in boat hulls. With high tensile strength at weld points and excellent corrosion resistance, these alloys are ideal for use in marine applications.

The 6XXX series offers two more alloys of marine grade that are particularly well suited to seawater, 6061 and 6063. The former, with a yield strength of 40,000 psi, is among the most commonly used aluminum alloys across all industries, and is again a top choice for boat hulls. The latter, while not as strong as 6061, does offer greater formability, and features a high surface finish that is good for anodizing.